What do corn, poop, and microalgae have in common? Well, other than making up the best opening sentence ever written, the answer is: biofuel.

(If you thought it was a three-piece folk band from the 1960s, please send a subscription to your newsletter.)

We live in a world that runs on fuel. Whether that is the electricity that runs our computers or the fuel that gets us to work – and creates the road that got us there – as well as powering industry, society and, well, climate change. Society has an ever-increasing demand for fuel, and now more than ever, demand for a fuel that is sustainable as well as environmentally sound.

But before there’s talk of biofuel, let’s visit biomass and the humble fire. Biomass is any organic matter used as fuel, especially for energy generation. The wood we burn for heat is biomass at work.

But, we have needs far beyond what the energy of a small fire can provide, and because of this, we not only need something that works a little better, but something more sustainable.

For many years, it was thought that petroleum-based fuel was the answer to this. And really, it was, until the world became aware of depleting oil reserves, skyrocketing costs and the wars associated with controlling the world’s oil supply, not to mention its continued use is a consistent attack on the earth’s climate.

Alternatives to this fuel type have been researched intensely for at least the last two decades, and while some solutions require new infrastructure or a new way of viewing energy generation, some have focused research on finding something that will work with what we already have; a fuel that will fill your car, without having to change much about your routine. And as Canadians consumed 110 billion litres of refined petroleum products in 2018 (80 per cent of which was transportation fuels), having an almost identical alternative would be a blessing, even if it was only a part of the solution.

So, the search for biofuel (any fuel created by biomass) began.

Biofuels can be split into two groupings based on the part of the cell from which the fuel is derived: bioethanol, and biodiesel. Cells, the building blocks of life, contain three main molecular components: proteins, lipids (fats) and carbohydrates. If you are making bioethanol – which is often from corn – you are using carbohydrate molecules. If you are interested in biodiesel, you look to the lipids.

Research into biofuels has come far enough that there is now what is referred to as ‘three generations’ of biofuels – and that’s where garbage and sugar come in. Also the corn, poop and microalgae. And yes, that was just another excuse to write that.

The first generation of biofuels came from edible crops – and that was its downfall. While the fuel created by corn, and sugarcane, produced an effective fuel, there was an ethical dilemma along with it; there are not only enormous demands for energy, but for food as well. By using food crops as fuel, farmland that could be used to feed animals and humans was lost. And it was too valuable a loss.

So, here comes the middle child. Second Generation, learning from the first, went exactly in the opposite direction – poop and garbage. Okay, municipal waste, but who could pass up the opportunity to write it again? Instead of looking at the before – the food – they examined ‘the after’.

But really, in a less childish way, second generation biofuels are based in non-edible (what an understatement) lignocellulosic (dry plant matter) biomass. Biomass used for production of second-generation biofuels is usually separated into three main categories: homogeneous, such as wood chips; quasi-homogeneous, such as agricultural and forest residues; and non-homogeneous, including low-value feedstock and municipal solid wastes. Yes, once again…

Second generation fuels are still consistently researched and gaining ground, but now, so is third generation: and that third generation – algae – is about to turn heads. Like the youngest always does, shows up when no one wants them. (Is this experience talking? No, why do you ask?)

But not only is microalgae beginning to revolutionize thinking in many industries, but Sudbury’s microalgae specifically.

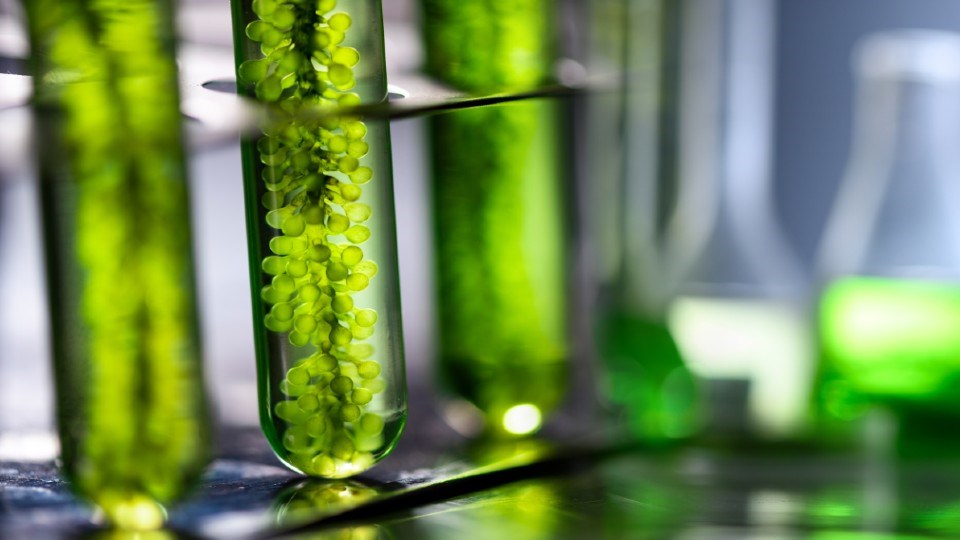

Microalgae is an umbrella term that includes microscopic plants, bacteria, and diatoms (a type of algae, and the only organism on the planet with cell walls composed of transparent, opaline silica). Chlorophyta, or ‘green microalgae’ is another umbrella term under the microalgae umbrella – let’s call it a parasol – and it includes only microorganisms that present green pigments.

Because there are 40,000 different types of microalgae, and some that may be undiscovered, the term ‘green microalgae’ works best for our purposes.

The Living with Lakes Centre, in partnership with Ongen, a Sudbury-based company and laboratory, are researching the hidden talents of Sudbury’s green microalgae, and one project has involved the mining industry in every step – in its own way of course.

“Our lab does something different than most people,” says Sabrina Desjardins, one of the leading researchers on the project. “We have a lot of abandoned mines in Ontario, of course, so we actually go to some sites, some ‘mine influenced’ sites and take samples. It's called bio prospecting. And then we isolate different algae that we find in those environments.”

But it’s something about the algae in Sudbury: it’s built differently, the way its people are. Everyone thinks life is tough, so when they head north, it’s tougher. But if you live ‘up here,’ you’re born into tough. The same is true of the microalgae.

“We find that because they're from a stressed environment already, it's technically their optimal environment.”

So what does stress have to do with it? Well, everything.

When you are trying to extract a certain molecule, like lipids or carbohydrates, and you wish to do so effectively both by cost, time and material use, well, it would help if you could get the most out of every sample. If there were a way to significantly increase the amount of lipids available in each cell of microalgae – a way to stress them into survival mode, causing them to produce more of the molecule that will be extracted for biodiesel (see where this is going) then that would be a great way to make efficient use of each part of your processing.

Non-Sudbury green microalgae — let’s call it ‘southern’ — would find Sudbury’s mine-influenced sites a great stressor and inhospitable environment, but Sudbury’s green microalgae is used to it. And not just that, but it has already produced a natural increase not just in lipids and carbohydrates, but also in secondary metabolites. It is these metabolites that are being investigated for their medical benefits.

So what do we do to a green microalgae that is very capable of handling stress? Add more stress, of course. And this time, let’s get some carbon dioxide (CO2) involved. If you know your mining history, you know that is something Sudbury has in spades.

“Because green microalgae is photosynthetic,” says Desjardins, “it's just like any other plant cell, it needs carbon dioxide and sunlight to grow. So what we do is we use carbon dioxide from the Falconbridge smelter, and from Glencore. We take their off-gas from the smelter and pump it into tanks so that we can use the CO2 to grow the microalgae. So it's just like a closed loop circle.”

And a closed loop system, made of ‘waste’ products, is a very sustainable system.

The researchers also seek to try and amplify the lipids in the green microalgae in different ways to see if it is possible to get more; things like adding salt, or changing the pH of the environment in order to test the cells ability to produce lipids for its survival.

Once they have achieved the optimal lipid levels from the cells, the lipids are harvested. Timing is important here: “at the top of their exponential curve, we call that the stationary phase. So they're not growing anymore. Right before then is when you usually get the most lipids in the cell. You have to find that balance between getting the most biomass and then getting the most of the component that you want.” Essentially, you want them full from dinner, but still hungry for dessert.

Then, the lipid extraction, and classification. If you’ve ever read a nutrient label, you know the difference between saturated and unsaturated fat. The saturated and mono-unsaturated fats in green microalgae go on to be biodiesel, and those that are polyunsaturated are finding themselves involved in research elsewhere: vegan sources of omega fatty acids.

And now, your word of the day: transesterification. It is the process of extracting the oils and converting them into biodiesel by breaking the bonds linking the long chain fatty acids to glycerol, and replacing it with methanol.

And from there, a simple wave of the hand (or several years of hard research, trials, tribulations, failures and jubilations, your choice) and this biodiesel can get you where you need to go.

For now, the research is still young. Currently, biodiesel is often mixed with diesel, used as a blended fuel that does not stop but decreases the particulate matter and harmful emissions that result from its consumption. That’s not only of interest for those one the road, but again, those underground, as mines are consistently looking for ways to decrease infrastructure costs – and less emissions means less costly ventilation systems.

While the generations of biofuels continue to develop, and research continues to pursue alternative fuels, there is real potential for the mine impacted sites of Northern Ontario to offer something not found anywhere else in Canada: tough people, and tough microalgae. Or stressed people, and stressed microalgae. Again, your choice.

Jenny Lamothe is a freelance writer, proof-reader and editor in Greater Sudbury. Contact her through her website, JennyLamothe.com.