SNOLAB scientists have partnered with international peers to design software for an alternative to the standard mechanical ventilator in response to industry shortages and international need brought about by the outbreak of COVID-19.

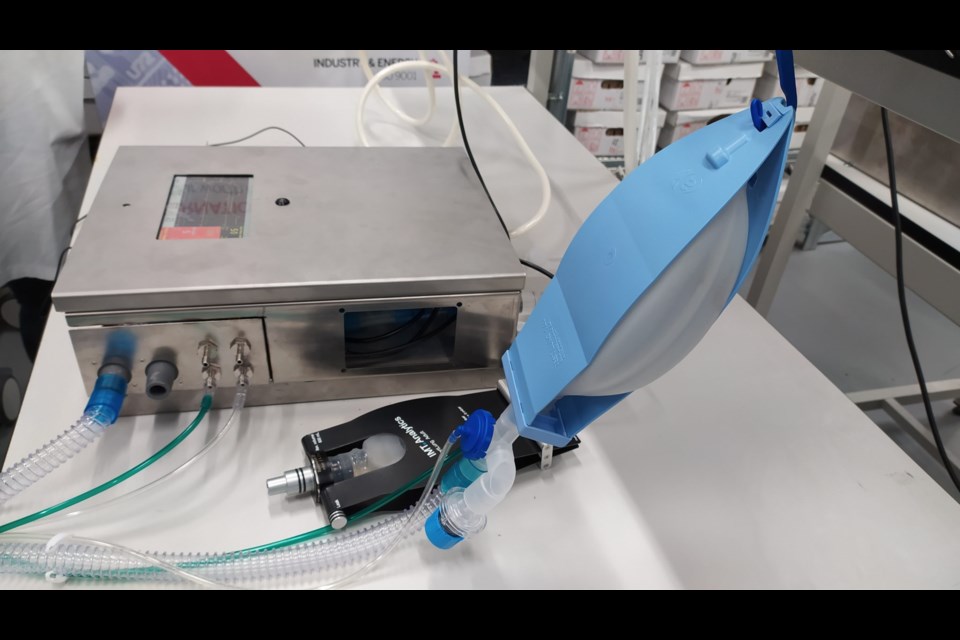

The Mechanical Ventilator Milano (MVM) is a simpler form of artificial respirator that uses pressure management rather than the standard volumetric delivery method offered by a motor, for added ease in both construction and usage. Its open-source design is currently undergoing testing for final verification to achieve medical certification in the USA, Canada, and Italy, with production expected to begin in early May.

Work on the MVM Project, as it has since been named, began when Italian physicist Dr. Cristiano Galbiati was quarantined in his home by the pandemic where he realized rather quickly the need for additional ventilators. He began forming a multi-national coalition capable of reformatting and restructuring the Manley Ventilator, originally designed by Robert E. W. Manley in July 1960.

The idea was to create a simplified, more affordable design relying solely on the medical air or oxygen available in Intensive Care Units as well as an external power source. To make it easier for countries to reproduce the product within the constraints of their existing supply chains, it was also designed using off-the-shelf-components, meaning those already being produced.

It is capable of limited modes of operation in comparison to pre-existing mechanical ventilators as described by the accompanying MVM Care website, designed with this crisis and demands of a similar nature in mind. That, however, was the point, explained Dr. Nigel Smith, executive director at SNOLAB in a recent interview with Sudbury.com.

“In a non-crisis situation, you want your ventilator to do everything,” he said. “You want it to be capable of supporting the medical teams in whatever they need to provide care to the patient. The MVM is a simpler design.”

Products will still need to meet strict regulations as they will be used for a medical device, said Smith, it just makes finding a comparable valve, for instance, a little easier.

Canada became involved in the project by late March, through Galbiati’s pre-existing relationship with fellow member of the Global Dark Matter Collaboration, Nobel laureate and former director of the Sudbury Neutrino Observatory, Dr. Arthur B. McDonald.

McDonald rallied the efforts of Canadian physicists behind the cause, including representatives of the SNOLAB, Chalk River Laboratories (CRL), Canadian Nuclear Laboratories (CNL), and the TRI-University Meson Facility (TRIUMF).

In addition to sitting on the international committee, SNOLAB has taken leadership in facilitating communication between the groups as well as sharing information on the project through the MVM Care site and associated social media accounts. The team has also been integral in the creation of a stand-alone gas mixer that would accompany the ventilator, allowing it to be more portable.

TRIUMF, on the other hand, has been focusing on the MVM’s control systems and software, said Smith, while CNL has been playing a key role in building the hardware and prototypes.

“One of the questions is, well how come a bunch of physicists think they can help,” posed Smith. And the answer is simple - this is something they already do.

A considerable part of dark matter research involves gas management and handling in developing the sophisticated control systems to make that control possible, said Smith. Working together in this format is also something the community is quite accustomed to, and with that researchers are very much aware of the limits to their knowledge and expertise.

With that in mind, Smith said MVM has grown to include clinicians, anesthesiologists, and manufacturing teams because, at the end of the day, they are the ones who will need to explain the device’s effectiveness to government and regulatory officials.

“It’s tremendous because it means, for a start, you are bringing in a very wide range of experiences, a very wide range of expertise, (and) a wide range of opinions sometimes but that is good.”

The collaboration has resulted in the production of five prototype models which will be used for final testing in hopes of achieving certification and approval.

At this point, Smith said participants of the MVM Project expect to fall back to more of an advisory role should they be needed at all.

All efforts by international laboratories have been independently funded up to this point, said Smith, but manufacturing would be a different story, especially given the volume to be produced. The initial expense, however, was in no way a deterrent.

When the project was initially proposed, he said there was no question whether any lab directors contacted would participate, SNOLAB included. Getting into the field of medical devices was not something Smith said he could have imagined even six months ago, but his team is used to challenging themselves, assisting for example in the field of genetics and mining innovation prior to the pandemic.

“SNOLAB has been well supported by the public and (we) want to contribute back,” he said. “This is obviously for the benefit of Canadians and the benefit of the world as well. It would be unconscionable not to engage everything that we can to support solutions in this crisis.”

Those looking to support production of the MVM Ventilator may do so through the project’s funding campaign here.